Artasa is a dedicated supplier of equipment and products to the entire Agro Industry in Panama, – however, with the main activity in the poultry sector.

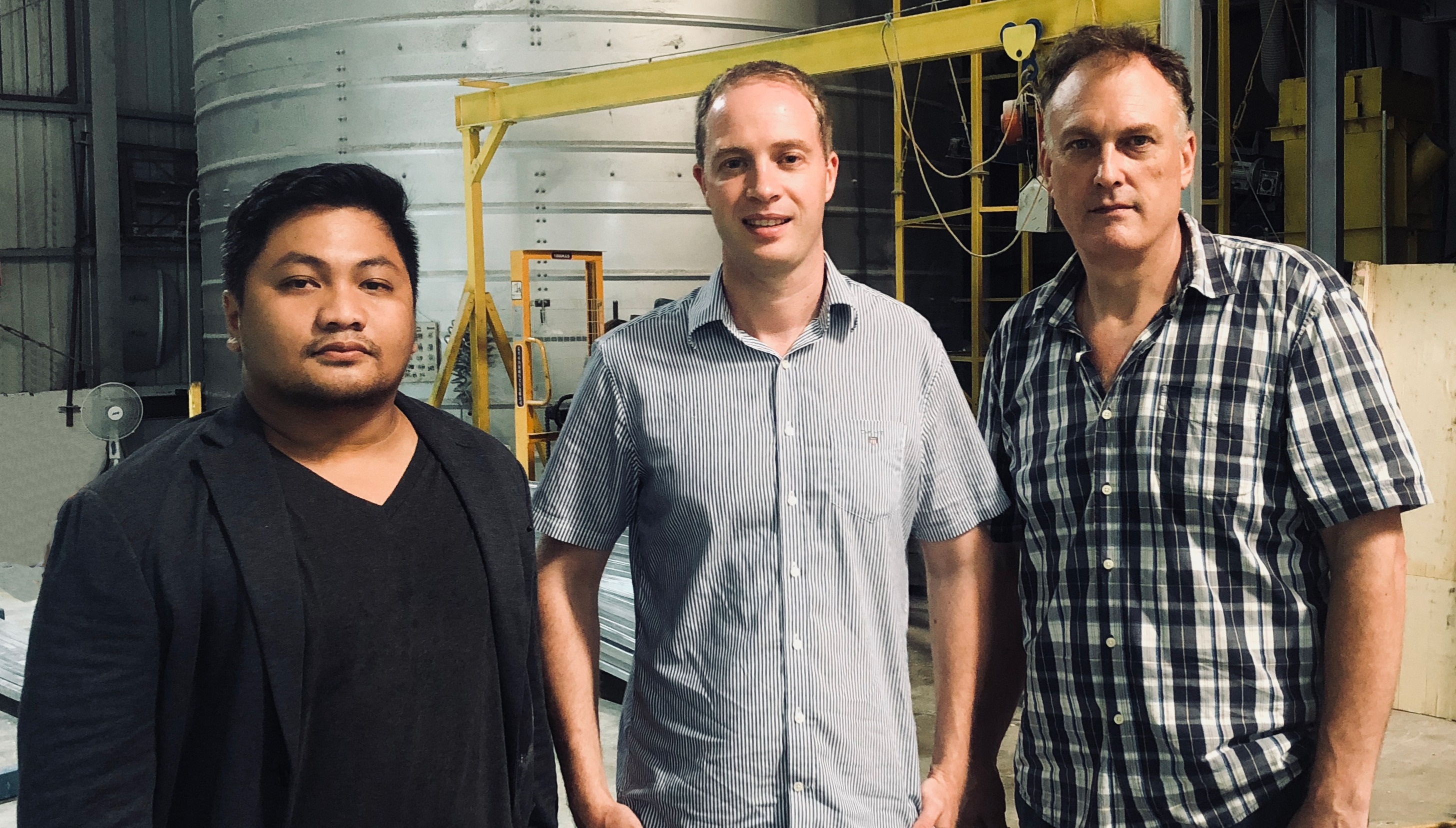

The company was started more than 30 years ago by Ingeniero Rodolfo E. Arosemena, who is still the main share holder of Artasa.

Being the exclusive representative for recognized international suppliers, Artasa is doing consultancy, sales, and providing aftersales service, ensuring that projects are handled safely from beginning to end.

When hatcheries in Panama want to expand or improve, contact Mrs. Ana Chew (General Manager) in Artasa, then you have taken the first step to a successful business.

A warm welcome to Artasa in the LINCO family.